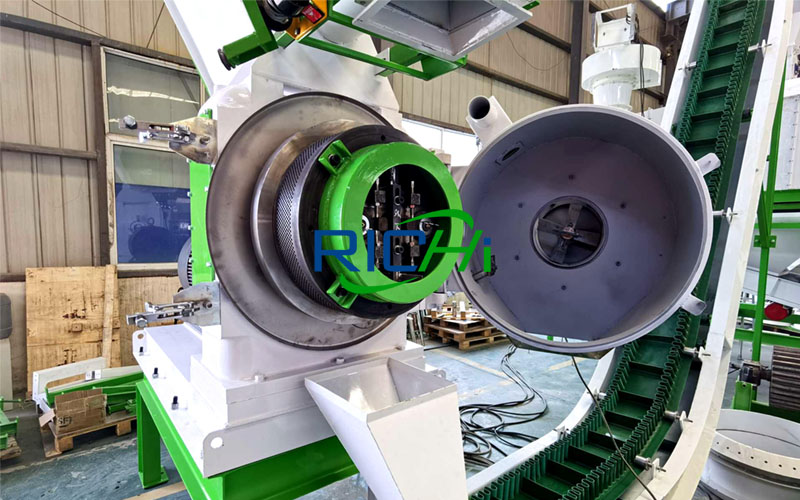

Adjusting method between ring die and press roller of wood pellet machine(direct, simplest and practical)

As long as it is a person who understands the equipment of wood pellet machine, if someone asks you what is the gap between the press roller and the ring die of the wood pellet machine? I believe most people will say: 0.3 ~ 0.5 mm, of course, this is only a quantitative adjustment, which can be used as a reference when adjusting. But if you really measure this gap according to the gap measurement method (such as probe method, capacitance method, etc.), I really convince you. In actual production, some customers asked about the measurement method, we usually teach the customer to use A4 paper to measure.

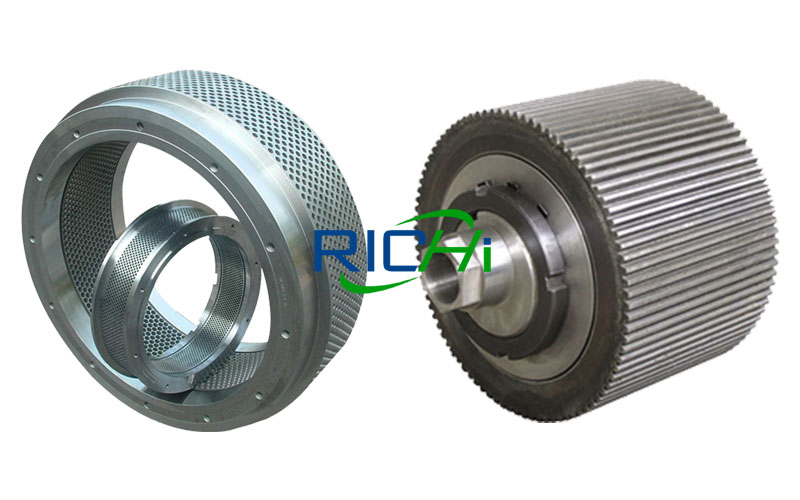

We know that the roundness of the ring die and press roller of the wood pellet machine is generally slightly deformed after heat treatment. When adjusting, the maximum outer diameter of the press roller should be in contact with the minimum inner diameter of the ring die. If the gap is adjusted according to this method, When 0.3~0.5 mm, the gap at the maximum inner diameter of the ring die will inevitably be too large. After the wood pellet machine is adjusted, you will adjust it again in less than two or three days, of course, as long as you are not too troublesome. Although this can reduce the wear of the pressing roller and the ring die, it also requires more time and frequent adjustments.

Never use the maximum outside diameter of the press roller to contact the minimum inside diameter of the ring die for adjustment, because once the maximum outside diameter of the press roller contacts the minimum inside diameter of the ring die, additional radial force (impact load) will be generated and abnormal metal friction will occur.

For RICHI’s ring die and press roller, these issues need not be considered. Because there will be a processing after heat treatment to ensure that the roller ring die does not lose its roundness. After many measurements, it is known that the maximum outer diameter and the minimum outer diameter differ by about 0.1mm, then the maximum outer radius and the minimum outer radius are different by 0.05mm This value has basically no effect on actual production, so it can be ignored.

Some articles transcripted on the Internet require that the outer surface of the pressing roller be in slight contact with the inner surface of the ring die, and it will appear to be non-rotating under the rotation of the main shaft.

RICHI Machinery teaches you the most direct, simplest and most practical adjustment method: tighten the maximum outer diameter point of the press rod and the minimum inner diameter point of the ring die with a little effort on the wrench. The new equipment is slightly tight, and the ring die is not changed after the ring die is replaced, or the ring die is not changed after the press roller. It is hard to close because there is a space between the wood chips, even if the ring die is tightly closed, the ring die will not contact the press roller.

It is good to follow the principle that the new ring die is less laborious and the old ring die is more laborious; although the gap between the pressure roller and the ring die is too small, the pressure roller and the ring die are easy to wear, on the contrary, if the gap is too large, it will cause difficulty in discharging. To reduce this little wear and tear, adjust the gap between the ring molding rollers frequently before starting the machine every day.

The unreasonable adjustment of the gap between the ring die and press roller of the wood pellet machine will also affect the service life of the equipment, and the following two conditions will usually occur.

1. The positioning pin of the roller frame plate is broken

Due to the extra radial force, the pressure roller of the wood pellet machine transmits the reaction to the pressure roller frame plate through the eccentric shaft of the pressure roller, so that the pressure roller frame plate bears periodic alternating stress, and the positioning pin of the pressure roller frame plate is worn and loosened. Make the screws of the fixed frame plate bear the shearing stress. Long-term shear stress will cause the frame plate screws and positioning pins to shear and fracture, or the four high-strength bolts fixing the pressure roller frame plate will become loose. As a result, the bolts fall between the stick molds, causing greater failure of the equipment.

2. The roller bearing is damaged

- The extra radial force is transmitted to the bearing through the pressure roller. Although the tapered roller bearing used to support the rotation of the pressure roller can bear a certain radial and axial load, the bearing generally suffers from fatigue pitting under normal load for a long time. Failure, and under the impact load, it is easy to occur due to the plastic deformation failure of the inner and outer ring raceways of the bearing and the local stress on the working surface of the ball exceeding the yield limit of the material.

- It is manifested as the bearing inner and outer rings, there are obvious uneven wear pits on the balls, and the rotation accuracy is reduced. If the plastic deformation exceeds a certain value, the bearing temperature rises rapidly, the grease is burnt, the bearing cage is deformed, and the bearing is stuck and becomes invalid. . Because the roller bearing is fixed by the inner ring and the outer ring rotates, if the additional impact load is obvious, there will be obvious crushing phenomenon in the bearing cage after the failure, and the bearing will eventually be burnt out.

- During the operation of the wood pellet machine, if the frame plate positioning pin is broken and the pressure roller bearing is damaged frequently, if there is no other obvious reason, it is generally because the ring die and the pressure roller are out of round and the gap between the two is adjusted too small.

It can be seen that the gap between the ring die and press roller not only affects the difficulty of discharging the wood pellet machine, but also affects the life of the wood pellet machine itself.

Pellet Production Line

Core Equipment of Wood Pellet Production Line

RICHI Pellet Machine For Sale

- Wood Pellet Mill For Sale

- Grass Pellet Making Machine For Sale

- Straw Pellet Machine For Sale

- Rice Husk Pellet Machine For Sale

- EFB Pellet Machine For Sale

- Organic Fertilizer Pellet Machine For Sale

- Cat Litter Pellet Making Machine For Sale

- Textile Cord Pellet Machine For Sale

- Paper Pellet Making Machine For Sale

- Pellet Maker For Pellet Stove