- RICHI PELLET MILL SERIES

Sawdust Pellet Mill

RICHI Machinery can provide a variety of sawdust pellet mill with different capacity. Up to now, our sawdust pellet machines have been exported to more than 110 countries overseas, such as the United States, Canada, Australia, Britain, India, South Africa, Angola, etc. If you are interested in the sawdust pellet machine, please contact us for a free sawdust pellet machine price list.

Sawdust is a by-product of the wood sawing process. However, in fact, sawdust is not widely recycled and reused due to its low combustion efficiency. With the popularization of pelletizing equipment and the development of pellet market, by making sawdust into pellets, it becomes a high-quality biofuel product-sawdust pellets or wood pellets.

RICHI Sawdust Pellet Mill For Sale, Since 1995!

We are a professional sawdust pellet machine manufacturer and exporter in China. Customers all over the world choose us not only for our product, but also for our services. RICHI not only provide sawdust pellet mill for sale, but also provide our customers with a complete turnkey project on how to make wood sawdust into pellets.

Contact us, what you get is not only RICHI equipment, but also a guarantee for your business.

BRAND

RICHI ®

MODEL

MZLH Series

CAPACITY

300KG~5TON PER HOUR

POWER

37~300KW

Sawdust Pellet Mill For Sale

If you are going to buy a sawdust pellet machine and set up your own pellet factory to make sawdust pellets, RICHI will give you guidance in all aspects:

how to identify and select excellent sawdust pellet machine manufacturers; the precautions for purchasing sawdust pellet mill; how to establish your own sawdust pellet production plant ; how to make pellets from sawdust; etc.

Contact Us:

- Office Add: E-commerce Industrial Park, Zhengzhou City, Henan Province, China

- Factory Add: Longhai 2nd Rd & 10th St, Longting District, Kaifeng City, Henan Province, China

- enquiry@pelletingmachine.com

- +86 185 7410 3366

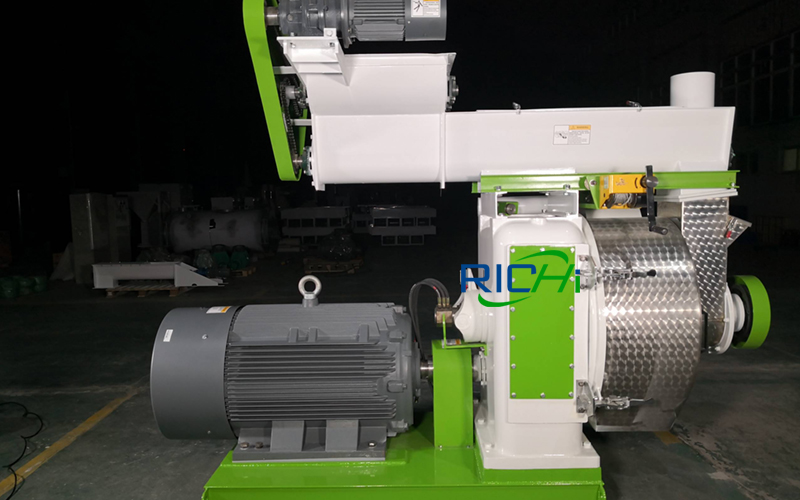

RICHI Sawdust Pellet Mill Machine

- Introduction

RICHI sawdust pellet machine for sale is used to make different sizes of sawdust fuel pellets. New energy fuel pellets are mainly used for power generation in power plants, home heating, and so on. In order to achieve low carbon emission, more investors choose to use green energy – sawdust pellets. For this machine, RICHI offers installment guidance and design layout for free. Contact us to get the latest sawdust pellet machine price.

- Structure

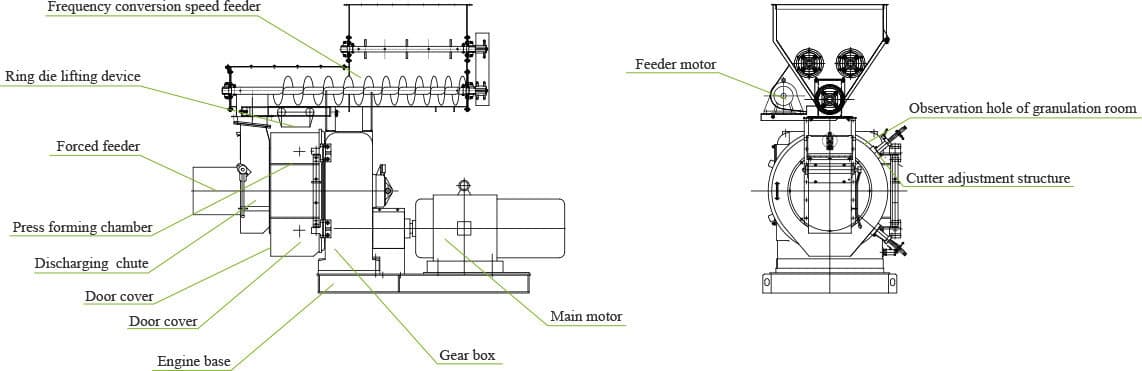

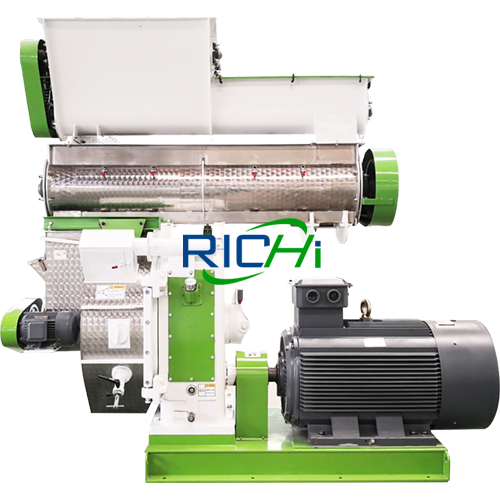

The sawdust pellet mill is composed of a pellet machine frame, a large reduction box, a bearing chamber, a feeding cover, a discharging part, a motor, a pressure roller assembly, and a mold.

The sawdust pellet press is operated in a direct connection with a motor. The motor is connected to the shaft of the reducer through a gear coupling. After a 90° change of direction, the horizontal motor drives the vertical casting hollow transfer spindle, and the spindle drives the roller to roll the mold. The inner surface completes the pelletizing process.

When sawdust pellet press working, the sawdust or other biomass material falls vertically from the feed inlet, and the material is continuously and uniformly distributed on the surface of the mold cavity (the contact surface between the pressure roller and the mold) through the rotation of the pressure roller, and the powdery material is crushed by the pressure roller holes through the mold (holes evenly distributed on the inner surface of the mold). In this process, the material is subjected to high pressure and high temperature to produce physical changes or appropriate chemical changes (according to the material), which promotes the powdery material to form a continuously elongated cylindrical solid body, and then the pellets are cut by a knife and discharged from the discharge port. The compaction process of the pellets is completed.

- Parameter

All the sawdust pellet mill for sale, we have the following parameters, but when different raw materials are used, the capacity is different, and the related equipment that needs to be matched may also be different. Therefore, according to the requirements of raw materials and capacity, contact us for final guidance and suggestions.

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

|---|---|---|---|---|---|---|

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Pellet Machine Power | 37KW | 55KW | 110KW | 160KW | 250KW | 280KW |

| Capacity(wood sawdust,biomass) | 300-400KG/H | 500-700KG/H | 1.0-1.2 T/H | 2.0-2.5 T/H | 2.5-4 T/H | 3-4.5 T/H |

| Capacity(grass,straw) | 600-800KG/H | 800-1000KG/H | 1.5-2 T/H | 3-4 T/H | 5-7 T/H | 8-10 T/H |

| Capacity(organic fertilizer) | 1-2 T/H | 3-4 T/H | 5-6 T/H | 7-8 T/H | 9-10 T/H | 10-12 T/H |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

| Weight(KG) | 2500 | 3500 | 4000 | 4500 | 5000 | 5500 |

| Dimension(mm) | 2200*900*1300 | 2500*1100*1600 | 2800*1150*1730 | 3000*1260*1860 | 3300*1500*2000 | 3500*1600*2180 |

Application Range of Sawdust Pellet Mill

- Application

The raw materials of the pellets produced by the sawdust pellet mill can be logs, branches, shavings, wood chips, sawdust, and other forestry wastes.

This kind of pellets are mainly used in biomass power plants, household heating (mainly used in pellet heating stoves), fuel pellets (if the raw material is fruit trees, the pellets produced are generally used for barbecue), animal supplies (horse bedding pellets), and many more.

Therefore, RICHI recommends that you first clarify what kind of raw materials you are using and what market the pellets produced are going to sell.

Of course, we are not only a manufacturer of sawdust pellet mills, we also provide customers with complete pellet production solutions, just tell us your raw materials and expected output.

Why Customer Choose RICHI Sawdust Pellet Mill

- Features

- Anti-Arch Structure In Sawdust Pellet Making Machine

On the top of the sawdust pellet machine with a anti-caking bin . Inside the bin, there have two rollers for breaking the sawdust to avoid raw materials becoming cake . And the bin can keep sawdust pellet machine working more smoothly.

- Sawdust Pellet Mill Force Feeder

Because the wood sawdust is too light , so it is difficult to enter into the sawdust pelleting chamber , so we add a force feeder here to improve the efficiency of the sawdust pelleting process.

- Sawdust Pelleting Chamber

Optimized structure of the sawdust pelleting chamber ensures the uniformity of the material and maximizes the working potential of the sawdust pellet machine. Through the pressure between ring die and rollers, to make pellets. After pelleting , the sawdust pellets temperature is high about 70-80℃. And have 98% qualified pellets, 2% powder.

- Ring Die And Press Roller

This is the 304 stainless steel ring die, it determines the final sizes of the feed! For the ring die, it has the following data: “d”, which refers to the diameter of the ring die ; “h”, which the the depth of the hole, or you can say the thickness of the hole. (d/h=compression ratio).

- Sawdust Pellet Mill Cutting Device

To control the length of final sawdust pellets , means through adjust the distance between cutter and ring die to get the different length of sawdust pellets.

- Steam Discharging Outlet

When the sawdust pellet mill machine running , inside the pelletizing chamber ,the temperature is very high, and the moisture of sawdust enter into the pellet chamber is 15%-17% ,so it will produce a lot of steam . In order to keep the pellet machine good working, so we open a hole here, to connect with draught fan and cyclone, to exchange the steam inside the chamber and also reduce the temperature in the chamber.

- Siemens Motors ,SKF Bearings

Siemens electric motors are synonymous with quality, innovation and the highest efficiency. The high efficiency level reduces energy consumption and directly saves costs for users. High protection level to ensure the safety and reliability for users.

Sawdust Pellet Mill For Sale On Stock In RICHI

Trusted RICHI Sawdust Pellet Mill For Sale

26Years Experience of Manufacturing and Exporting

“We have 26+ years’ experience of sawdust pellet mill machine, and have exported 110+ countries, such as USA, Canada, Indonesia, Australia, Netherlands, New Zealand, Greece, Italy, Angola, South Africa, Turkey, UK, Germany, Malaysia, Thailand and so on.”

Full Set of Certification

“RICHI has pass through the CE&IOS 9001 Certification, All the sawdust pellet machine for sale has tested before delivery.”

Support Delivery Anywhere in The World

“RICHI Machinery can ship the sawdust pellet making machine to your port in your country, we supply the FOB & CIF Price. Just contact us for more details.”

Full Support on Installation &Training

“We provide complete sawdust pellet machine for sale, installation at the customer’s local area and promise to train – ‘how to make sawdust pellets with sawdust pellet mill’ until the customer is proficient in operating the pelletizing system.”

Related Equipment Of Sawdust Pellet Mill For Sale

Sawdust Pellet Mill For Sale – The Related Guide

Sawdust Pellet Mill For Sale South Africa

The project is a 10 tons per hour customized automatic sawdust pellet production line with a competitive price. The customer’s main production raw materials are some waste wood, which is relatively large and contains impurities such as iron nails.

Therefore, if you want to make wood sawdust pellets, you must first slice and crush them. We have specially customized the cleaning section for customers, which can screen out iron nails, then directly slice and crush the waste wood, and then crush it again with a high-efficiency sawdust hammer mill to meet the granulation requirements.

The core equipment of this sawdust pellet plant is three MZLH768 ring die sawdust pellet press, with a single sawdust pellet mill machine output of about 2.5-4 tons/hour and a power of 250kw. It is our high-performance pelletizing equipment, and it is also the sawdust pelletizing equipment recognized by customers all over the world.

Sawdust Pellet Making Machine in India

RICHI’s professional installation team helps customers install and solve problems in the installation process.

- We send two technical and installation engineers to guide the installation;

- After installation and commissioning, we have trained the customer’s workers how to operate the entire pellet production line;

- Train workers how to maintain and protect pellet production equipment;

- According to the characteristics, we will formulate a complete maintenance rule for you, including how to maintain, when to maintain, and who to maintain;

- Our company’s after-sales department will regularly call India customers to inquire whether maintenance is needed and give suggestions;

- In addition to wearing parts, our company provides 1 year free warranty and permanent free technical support.

Sawdust Pellet Mill For Sale Australia

In 2021.01.21, the contract was signed for the 2-2.5t/h customized wood sawdust pellet processing line project. The customer has just entered the biomass pellet fuel processing industry. During the negotiation, we learned that the customer had a negotiation with 12 wood sawdust pellet machine manufacturers. RICHI was the last to enter his list of cooperation, but eventually became the most trusted manufacturer of China’s wood biomass pellet production line by customers.

There are many reasons why customers choose RICHI. In addition to RICHI’s product quality and brand awareness in many regions, customers also value our full consideration of him. In addition, due to the limited budget of the client, in order to ensure the quality and service life of the equipment configuration of the entire wood sawdust pellet fuel production line, for the pre-treatment stage of wood sawdust, the client purchases second-hand equipment in nearby areas, such as (wood peeling equipment, wood splitting equipment).

In addition, this 2-2.5 tons per hour biomass wood sawdust pellet plant strictly complies with Australian electrical standards. The final sawdust pellet factory also equips each device with an emergency stop system and an independent power switch to ensure safe operation.

How To Make Wood Pellets From Sawdust

With the development of pelletizing technology, the production of sawdust pellets has become more and more simple, you only need to pay attention to the following points:

- Preparation of raw materials. If your raw materials are relatively large wood logs, then in the first step you need equipment that can peel and slice the trees; then use a shredder to crush the relatively large pieces of wood to sawdust below 5mm; if your raw materials are some forest waste, small branches, wood chips, etc., you can crush them directly without chipping.

At this time, attention should be paid to the moisture content of the raw materials, and then if the wood sawdust are too wet, it needs to be dried to a moisture content of about 8-12% (note: the moisture content can be tested with a moisture meter). If you only make small-volume pellets, you can spread the sawdust on the ground and let it air dry. - The process of pelletizing. Start the wood sawdust pellet mill, and evenly send the sawdust into the hopper of the pellet mill machine through the conveying equipment. The rotating ring die and press roller squeeze the sawdust and force it through the die hole. The high pressure will make the pellets compact, and the high temperature will melt the lignin in the wood sawdust and become sticky. Therefore, the wood sawdust produced have high pellet density, smooth and even bright surface.

- After the pelleting is completed. The pellets just coming out of the sawdust pellet mill are very hot, so they must be cooled to room temperature before use or storage.

You can find that making pellets with sawdust is just an easy task! But sawdust pellets can save you a lot of costs, and even make you profit. So it is wise to buy a sawdust pellet mill now!

Can I Put Sawdust In A Pellet Stove?

Generally speaking, any stoves can be burned with sawdust. However, in modern society, stoves are divided into many types according to their use and fuel types. Therefore, the fuel of household pellet stoves is sawdust pellets or other types of pellet fuels, such as switchgrass pellets, cherry pits, and alfalfa pellets. On the one hand, the compressed pellets have more combustion value than sawdust; on the other hand, it is more convenient to use pellet fuel at home and there is no dust.

The fuel pellets of household pellet stoves are all made by sawdust pellet mill. This kind of pellet fuel is easier to store; it has a large calorific value; it does not contain sulfur and phosphorus and does not corrode the boiler; it is clean and hygienic, convenient to feed, and reduces the labor intensity of workers. Learn more about pellet maker for pellet stove >>