Wood Fuel Pellet Making Machine

RICHI Machinery is a fuel pellet machine manufacturer with more than 26 years of experience in China.

Especially used in the production of pellet fuel, suitable for various organic materials.

We have sold wood fuel pellet making machine to many countries, including the United States, Canada, Australia, New Zealand, and the United Kingdom. If you are interested in our fuel pellet making machine, please contact us for a free quote.

Fuel Pellet Machine

Pellet fuel is a heating fuel made by compressing and extruding organic biomass raw materials through a fuel pellet machine. The most commonly used type is wood pellets. As a form of wood fuel, wood pellets are usually made from compacted sawdust or other waste generated from sawn wood and other wood products.

Other woody biomass energy sources include palm core shells, coconut shells, and treetops and branches remaining after removal of whole trees or after logging. Even the of various crop residues can also be used as raw materials for granulation.

The particles are very dense and can be prepared with low water content (less than 10%), allowing them to be incinerated with very high combustion efficiency.

BRAND

RICHI ®

MODEL

MZLH Series

CAPACITY

0.5-5TPH<Customizable >

POWER

37~300KW

MZLH320 series fuel pellet making machine ensures high capacity and efficient control of the pelleting process. The fuel pellet making machine is dimensioned for large and designed with exchangeable wear parts.

- Power: 37KW

- Capacity: 600-800KG/H

- Pellet Size: 6-12mm

MZLH350 series fuel pellet making machine has wide adaptability. According to different raw materials, different pellets can be produced. Larger feeders increase production capacity and ensure production efficiency.

- Power: 55KW

- Capacity: 800-1000KG/H

- Pellet Size: 6-12mm

This ring die electric wood fuel pellet making machine is recommended for fuel pellet production line. Due to the power and voltage, it is not recommended for household pelletizing. It is very suitable for making wood pellets, biomass pellets, organic pellets, and other pellets.

- Power: 110KW

- Capacity: Capacity: 1.5-2T/H

- Pellet Size: 6-12mm

The MZLH520 series fuel pellet making machine has a larger ring die and pelletizing chamber to ensure high-efficiency pine wood pellet production. In order to adapt to lighter raw materials, we have added a forced feeder.

- Power: 160KW

- Capacity: 3-4T/H

- Pellet Size: 6-12mm

MZLH768 series large commercial fuel pellet making machine is mainly used for the production of biomass pellets, wood pellets, sawdust pellets. Enlarged feeders and larger ring die sizes are more suitable for fuel pellet production plants.

- Power: 250KW

- Capacity: 5-7T/H

- Pellet Size: 6-12mm

RICHI wood pellet press for pellet fuel for sale. 26 years of pelleting plant experience, professional design and manufacturing team, overseas installation engineers, competitive factory direct sales prices. Advanced pelleting process technology.

- Power: 280KW

- Capacity: 8-10T/H

- Pellet Size: 6-12mm

Welcome to Visit RICHI Fuel Pellet Machine Factory

RICHI supply wood pellet making machine, sawdust pellet machine, biomass pellet machine, fuel pellet machine for sale. We are the top5 fuel pellet making machine manufacturer in China, Contact Us get the best price.

RICHI Fuel Pellet Machine For Sale

The fuel pellets machine is a device used to manufacture wood fuel pellets or biomass pellets. According to the different raw materials, only need to replace the ring die and adjust the cutter distance to produce different pellets to meet the demand. For example: wood, straw, rice husk, palm shell, etc.

The reason why customers choose RICHI’s fuel pellet mill is not only because we have high-quality products, we can provide perfect fuel pellet production solutions according to customers’ different needs and different raw materials, and even our after-sales service is also our major Highlights.

All our fuel pellet machine for sale has first-class technology; solid frame; stable motor. There is also a professional overseas installation team; training on the use of the pelleting machinery. Of course we still have competitive prices by factory outlet.

Wood Fuel Pellet Machine Testing Video

You May Also Like Related RICHI Pellet Machine

Fuel Pellet Machine: Definitive Guide

What is pellet machine used for?

As the name suggests, this is a device used to produce pellets (the crushed raw material powder is recompressed into cylindrical pellets through high temperature and high pressure). It can be roughly divided into animal feed pellet mill, wood pellet mill, biomass pellet mill, fuel pellet machine, organic fertilizer pellet machine, or other types of pellet machine.

Can you make your own pellet fuel?

Generally speaking, most fuel pellets are made in bulk by industrial fuel pellet machine.

Because of the particularity of raw materials, most of them need to be re-shredded. Therefore, if you want to produce pellet fuel, you basically need a fuel pellet production line, and there are some necessary equipment, including fuel pellet machine, hammer mill, cooling and drying equipment. For individuals or families, power and space restrictions will be a big problem.

How do you make biomass fuel pellets?

In order to make pellets, the biomass material must first be cleaned to remove impurities. The clean biomass material is then ground or cut in a hammer mill into small uniform sizes, which must be smaller than the thickness of the pellets to be produced. These raw materials are then extruded into cylindrical pellets through the high temperature and high pressure of the fuel pellet machine.

How much does a pellet mill cost?

As a professional pellet machine manufacturer, RICHI needs to talk to some customers who want to buy fuel pellet mill or enter the pelleting industry for the first time.

Generally speaking, the decisive factor for the biomass pellet machine price is the capacity, but different raw materials also restrict the capacity. For example, for the same pellet making equipment, the output of grass-based raw materials is higher than that of sawdust raw materials. Different raw materials require pretreatment processes, such as wood chipping and crushing. Through different display methods and different natural material processing, we can design various schemes and configurations to ensure the most suitable for customers.

So what is important to us is, what are your raw materials and expected production capacity? Contact us for the quote of fuel pellet mill for sale and customized wood fuel pellet production plant.

How is wood turned into biomass?

We define wood biomass as any wood-derived product (softwood or hardwood) that can be converted into energy through direct combustion or gasification; solid fuel obtained through pelletization; or liquid fuel through countless processes.

Although wood biomass may include any part of the tree, the cost difference of the various components is a major limiting factor. Generally, biomass used for energy and fuel production comes from four main sources:

- Manufacturing residue

- Non-commercial timber logging residues

- Post-consumer wood waste

- Urban and agricultural wood waste.

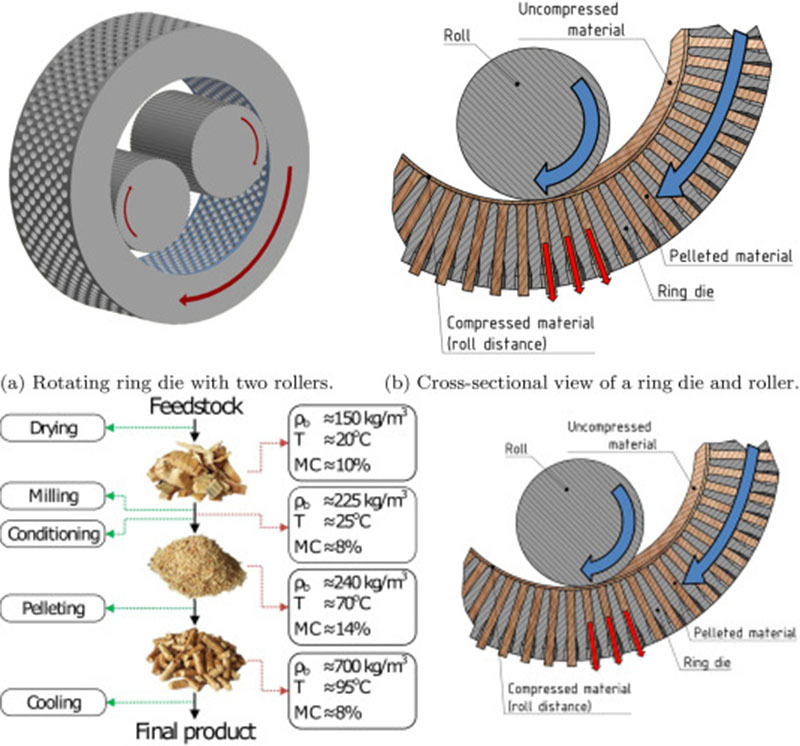

How does fuel pellet machine work?

The crushed raw materials (wood chips or biomass materials) enter the fuel pellet machine through the feeder. The high-speed rotating ring die distributes the incoming raw materials on the inner wall and drives the pressure roller to rotate together. The pressing roller squeezes the material to the ring die and extrudes it from the die hole, and finally is cut into the required length by the cutter. This process is called pelletizing.

- Material feeding: The wood material is fed into the machine through a hopper or conveyor belt.

- Drying: The material is dried to reduce its moisture content to the appropriate level, typically around 10-15%.

- Grinding: The material is ground into a fine powder to improve its flowability and reduce the size of any large particles.

- Pelletizing: The fine powder is fed into the pelletizing chamber where it is mixed with a binding agent, such as lignin, and subjected to high pressure and heat. The pressure and heat cause the wood fibers to compress and bond together, forming dense, uniform pellets.

- Cooling: The newly formed pellets are cooled to room temperature.

- Sizing and grading: The pellets are sorted and graded by size and quality.

- Packing and storage: The finished pellets are packaged and stored for use as a fuel.

Can you burn wood chips in a pellet stove?

The direct burning of waste wood resources as energy to provide heat has existed since ancient times. It’s just that now society we invented the combustion furnace to maintain heat and save fuel.

And with the advancement of science and technology, people have found that pulverizing wood into pellets will greatly increase the burning rate and further increase the resource rate. Therefore, fuel pellets have become more and more widespread. Of course, the development and growth of the fuel pellet machine industry has also provided convenience to the entire society.

What is better hardwood or softwood pellets?

There are more and more fuel pellet manufacturers, and they usually indicate on the outer packaging whether the raw material is softwood or hardwood for people to choose. There is usually a concept that hardwoods are denser and therefore burn more heat. But the fact is that in the same combustion furnace, softwood particles have a higher heat output and lower ash than hardwood.

No matter softwood or hardwood, after being pelletized by fuel pellet machine, each has its own advantages and disadvantages. The most important thing is that people should pay attention to the raw materials of the pellets and the calorific value of combustion when buying fuel pellets. As for whether to choose softwood or hardwood pellets, it depends on personal preference.