Pellet Cooling Machine

- Brand Name: RICHI Counterflow Pellet Cooler

- Model: SKLN11*11, SKLN14*14, SKLN17*17, SKLN20*20, SKLN24*24

- Capacity: 1.5-2T/H, 3-5T/H, 5-8T/H, 9-12T/H, 13-18T/H

- Application: Cooling of high temperature pellet after pelleting

Counterflow Pellet Cooler

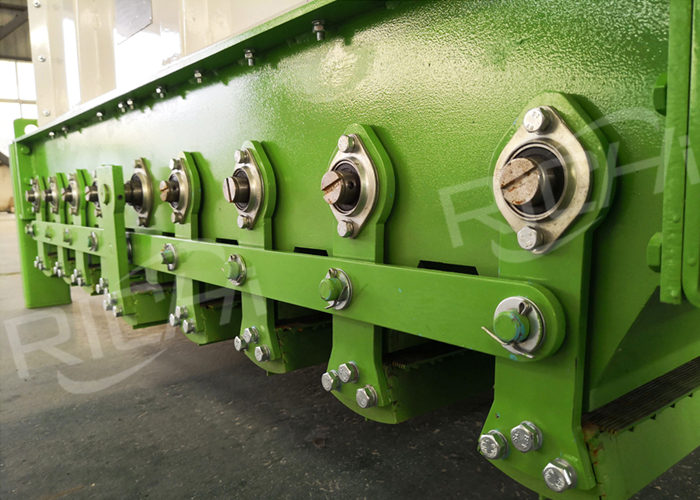

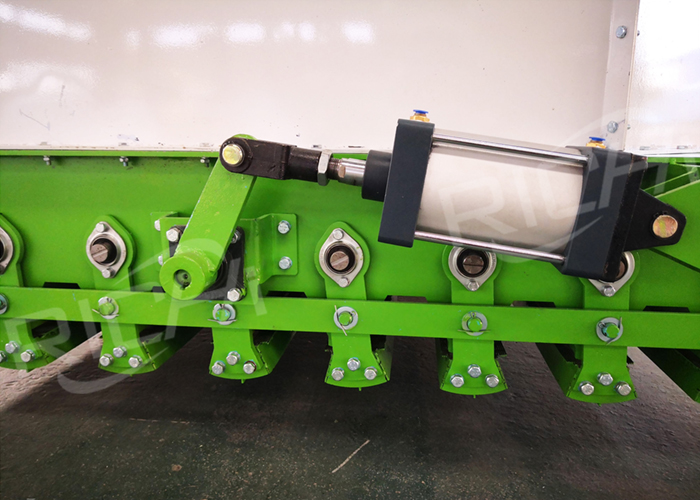

The counterflow pellet cooling machine is the most advanced pellet cooling technology in the world. It is a new generation of cooling equipment researched and developed, which is mainly used to cool high-temperature pellets after pelletizing.

The temperature of the cooled material is not higher than the outside temperature +5°C, and the precipitation rate is not less than 3.8%, which plays a good role in producing high-quality pellets and extending the storage time of pellets.

RICHI Pellet Cooling Machine

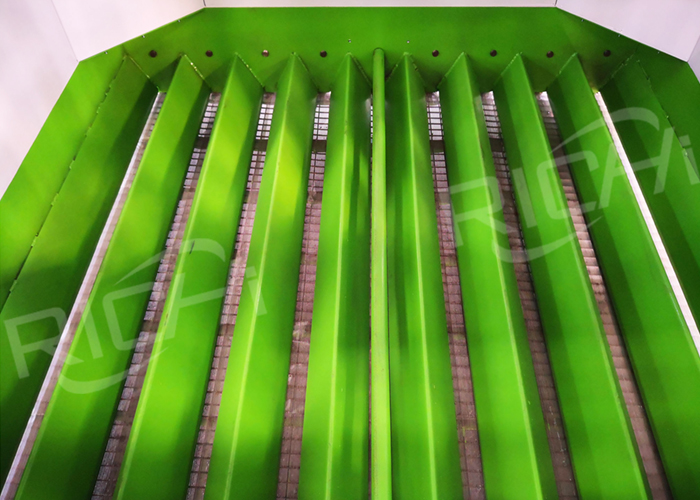

During the entire working process of the pellet cooling machine, the fan is always on, because the pellets flow from top to bottom, and the wind is opposite to the flow direction of the pellets, which flows from bottom to top, and the cold wind and the cold the pellets are in contact, and the hot air is in contact with the hot pellets, so this type of pellet cooling machine is called a counter-flow pellet cooler.

Due to the high temperature and moisture of the pellets in the silo, the pellets stay in the silo body for a period of time. Natural air enters from the bottom through the suction of the fan and passes through the material layer in the silo body for heat exchange. At the same time, the heat and moisture of the pellets are taken away by the fan to cool the pellets and reduce the moisture.

The counterflow pellet cooler has a good cooling effect and a high degree of automation;

Low noise, simple operation, and low maintenance;

The model widely used at home and abroad is an advanced replacement pellet cooling machine.

RICHI will configure suitable pellet cooling equipment according to the different needs of customers and the size of the output.

Pellet Cooling Machine Technical Parameters

Pellet Cooling Machine, Counterflow Pellet Cooler – RICHI Machinery

What is a pellet cooler?

How does a pellet cooler work?

Why use a pellet cooler in a wood pellet production line?

The function of the pellet cooler in the wood pellet production line is to cool off the warm as well as fresh generated pellets to room temperature level. This is essential for a number of reasons. To start with, the cooling process assists to strengthen the pellets, making them stronger and also less most likely to damage during storage or transportation. Second of all, cooling down reduces the moisture material of the pellets, which can reduce the danger of mold and perishing during storage. Lastly, cooling the pellets aids to decrease the friction between them, which can lead to smoother and much more effective handling in the production line.