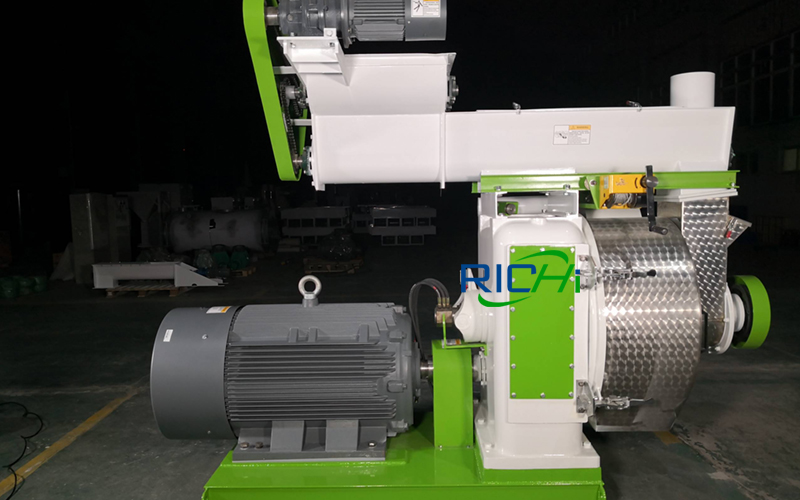

MZLH520 Series

Wood Pellet Maker

The MZLH520 series wood pellets maker has a larger ring die and pelletizing chamber to ensure high-efficiency wood pellet production. In order to adapt to lighter raw materials, we have added a forced feeder.

Find More Wood Pellet Maker For Sale

- Power: 380volt, 37kw, 50hz

- Application: Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Power: 380volt, 55kw, 50hz

- Application:Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Power: 380volt, 110kw, 50hz

- Application: Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Power: 380volt, 160kw, 50hz

- Application: Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Power: 380volt, 250kw, 50hz

- Application: Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

- Power: 380volt, 280kw, 50hz

- Application: Used for the production of biomass pellets, wood pellets, agricultural and forestry waste pellets

- Pellet size: 6-12mm

Wood Pellet Equipment Manufacturer

RICHI has 300 employees, including more than 80 professional technicians in mechanical design and manufacturing, feed processing technology, electrical automation, computer application, animal science, aquaculture, marketing, etc., which enables RICHI to have strong market development and Service, product development and manufacturing, project management and delivery capabilities.

RICHI has a variety of different types of feed production equipment, biomass wood pellet production equipment, and other related equipment, as well as turnkey projects. Pellet production lines range from 1 ton to 100 tons per hour. We can provide customized production lines according to customer needs, raw materials and production capacity.

Wood Pellet Maker Technical Parameter

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

|---|---|---|---|---|---|---|

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Pellet Machine Power | 37KW | 55KW | 110KW | 160KW | 250KW | 280KW |

| Capacity(wood sawdust,biomass) | 300-400KG/H | 500-700KG/H | 1.0-1.2 T/H | 2.0-2.5 T/H | 2.5-4 T/H | 3-4.5 T/H |

| Capacity(grass,straw) | 600-800KG/H | 800-1000KG/H | 1.5-2 T/H | 3-4 T/H | 5-7 T/H | 8-10 T/H |

| Capacity(organic fertilizer) | 1-2 T/H | 3-4 T/H | 5-6 T/H | 7-8 T/H | 9-10 T/H | 10-12 T/H |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

| Weight(KG) | 2500 | 3500 | 4000 | 4500 | 5000 | 5500 |

| Dimension(mm) | 2200*900*1300 | 2500*1100*1600 | 2800*1150*1730 | 3000*1260*1860 | 3300*1500*2000 | 3500*1600*2180 |

Why choose wood pellet maker machine from RICHI

Prevent

Connected to the air duct, there is a mesh in the box to prevent the finished pellets from overflowing

Frequency

Due to the characteristics of biomass raw materials, we have added a variable frequency feeder with anti-caking device

Motor

We promise that all motors use Siemens motors

Protect

Protect machine(Producting main shaft, rotor and ring die)

Lifting Device

This small lifting device can help user to replace the very heavy ring die and roller assembly

Ring Die

304 stainless steel ring die, corrosion resistance, Full automatic CNC ring die drilling machine and vacuum heat treatment technology

Can I Make My Own Wood Pellets?

Nowadays, due to the increasing awareness of environmental protection, waste reprocessing has become a sunrise industry. As long as there is sufficient raw material support, there is a very mature solution for establishing your own pellet production line. Buying a wood pellet maker to produce your own pellets is no longer a dream, we can customize pellet production process and provide turnkey pellet solutions. Startup pelletizing business with RICHI.

How does a wood pellet maker machine work?

The powdered raw material(all raw materials must be crushed into powder) enters the pellet machine chamber through the conditioner, is mechanically compressed under the action of high temperature and high pressure, and then polymerized and molded through the ring die hole, and finally cut into the required length by the cutter.

How much is a wood pellet maker?

As a professional pellet machine manufacturer, RICHI Machinery needs to talk to customers who want to buy wood pellet maker or enter the pelletizing industry for the first time.

Generally speaking, the deciding factor of the wood pellet machine price is the capacity, but different raw materials also restrict the capacity. For example, for the same pellet machine, the production of grass-based raw materials is higher than that of sawdust-based raw materials. Different raw materials require pre-treatment processes, such as wood chipping, crushing and drying. With different displays and different natural material processing, we can design various schemes and configurations to ensure that it is the most suitable for customers.

So the important for us is, what are your raw materials and the expected pellet capacity? Contact us for wood pellet maker prices and customized whole wood pellet production lines.

How to be a wood pellet manufacturer?

- Determine your raw materials. The raw materials determine the development direction of the pellet factory, such as the application of pellets and the design and planning of the production line.

- Determine the production capacity of the factory. Clarify the number of raw materials that can be received every day, investigate whether there are similar pellet manufacturers in the surrounding market, including their output, and examine the current market size and development prospects. Through this series of commercial investigations, the scale of the pellet production line can basically be clarified.

- Determine the land and electricity. Electricity is definitely the standard for industrial electricity. In addition to meeting the requirements of the production line, the size of the land also needs to reserve employee office areas, raw material storage areas, and finished pellet storage areas.

- Choose and purchase complete sets of equipment such as wood pellet maker. This is the simplest and most testing step. Buying good equipment and finding the right pellet machine supplier can make project operations more effective. Therefore, please note that you must choose a pellet production equipment manufacturer that truly has program design capabilities and overseas installation guidance experience, and sincerely solves customer problems.

Buy Wood Pellet Maker Today

Want to learn more about biomass wood pellets making machine? Contact us for more information about the pellet production process before purchasing pellet machine.

Wood Pellet Maker For Sale Worldwide

Before investing in a wood pellet manufacturing business, RICHI Machinery recommends that you should visit a wood pellet factory near you. You will find that a complete wood pellet plant will not only require a wood pellet maker machine but will also require wood chippers, wood sawdust making machines, wood pellets machines, pellet coolers, etc., depending on the raw material.

Wood Pellet Mill For Sale Canada

- Project name: biomass wood pellet plant

- Project Country: Canada

- Project Date: August 01, 2018

- Project capacity: 2-3T/H

- Particle size: 6-10mm

- Installation period: 15 days

- Pellet Factory size (L*W*H): 26m*10m*12m

- Main raw material: wood logs

Wood Pellet Plant in USA

- Project name: wood pellet manufacturers in USA

- Project Country: USA

- Project Date: November, 2020

- Project capacity: 10T/H

- Particle size: 6-8mm

- Installation period: 60 days

- Main raw materials: logs, sawdust, wood chips

RICHI Service

Start your wood pellet production business with RICHI Machinery. Turn your waste into profits.

From processing raw material to finished pellets, RICHI designs, builds, and installs complete wood pellet production systems.