Henan RICHI Machinery Co.,Ltd

RICHI pelletizing systems have a complete solution from small to large pelletizing runs that can be widely used. Feel free to contact one of our knowledgeable representatives to discuss your project!

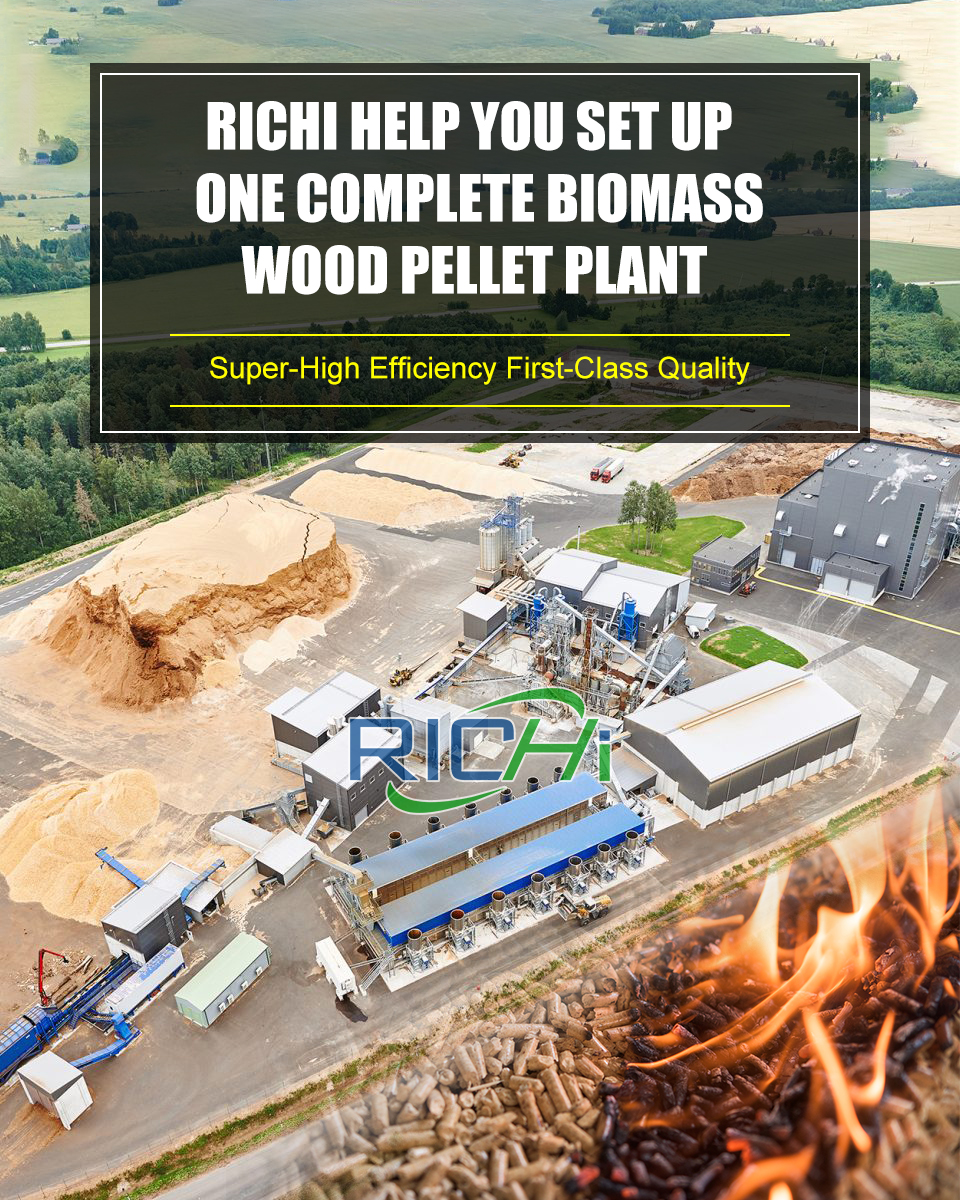

- Wood Pelleting Solutions

- Biomass Pelleting Solutions

- Organic Fertilizer Pelleting Solutions

- Sawdust Pelleting Solutions

- Animal Feed Pelleting Solutions

- Aquatic Feed Pellet Solutions

27+

Years of experience

100+

Pellet production related equipment

1000+

Successful case of pellet production

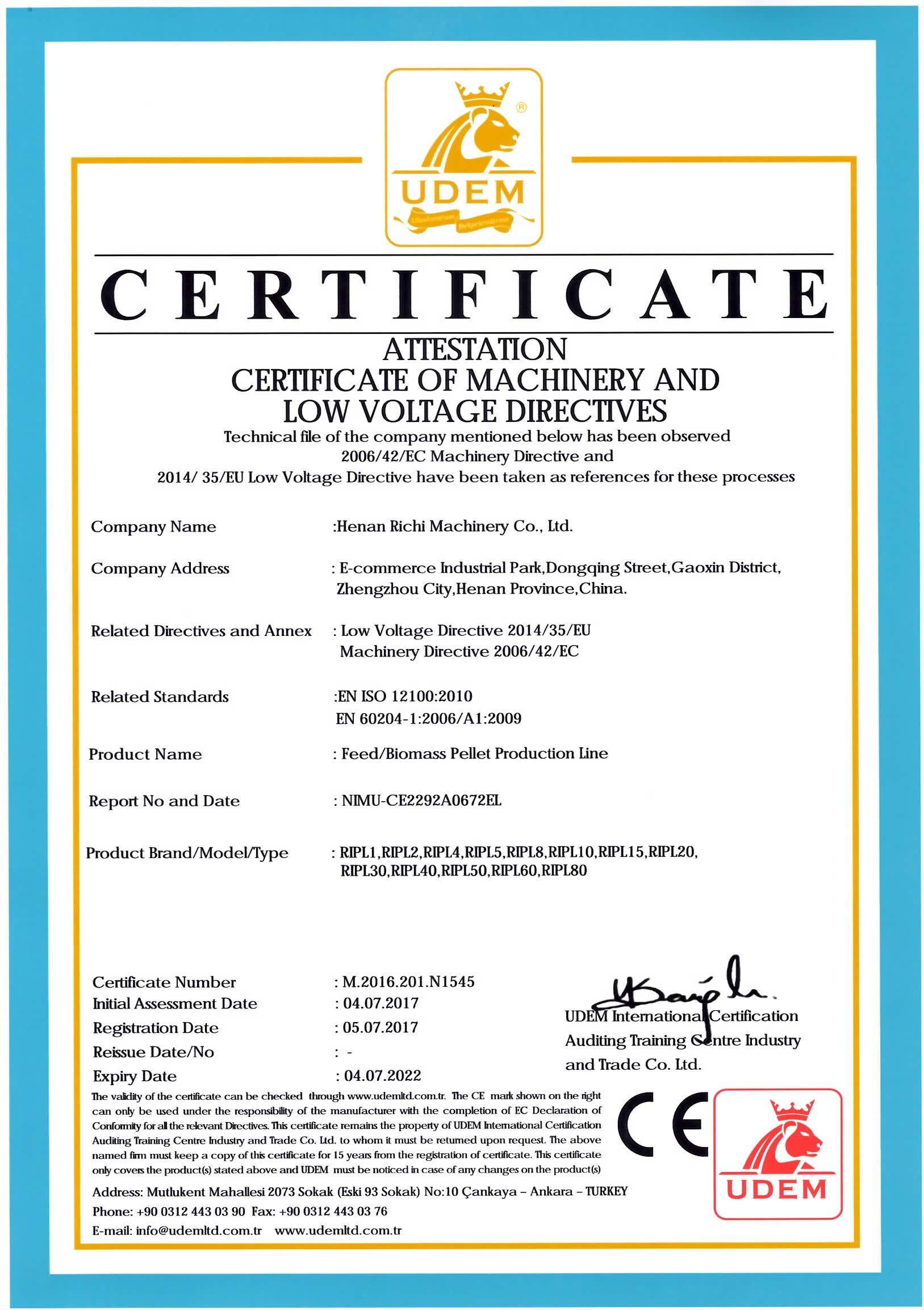

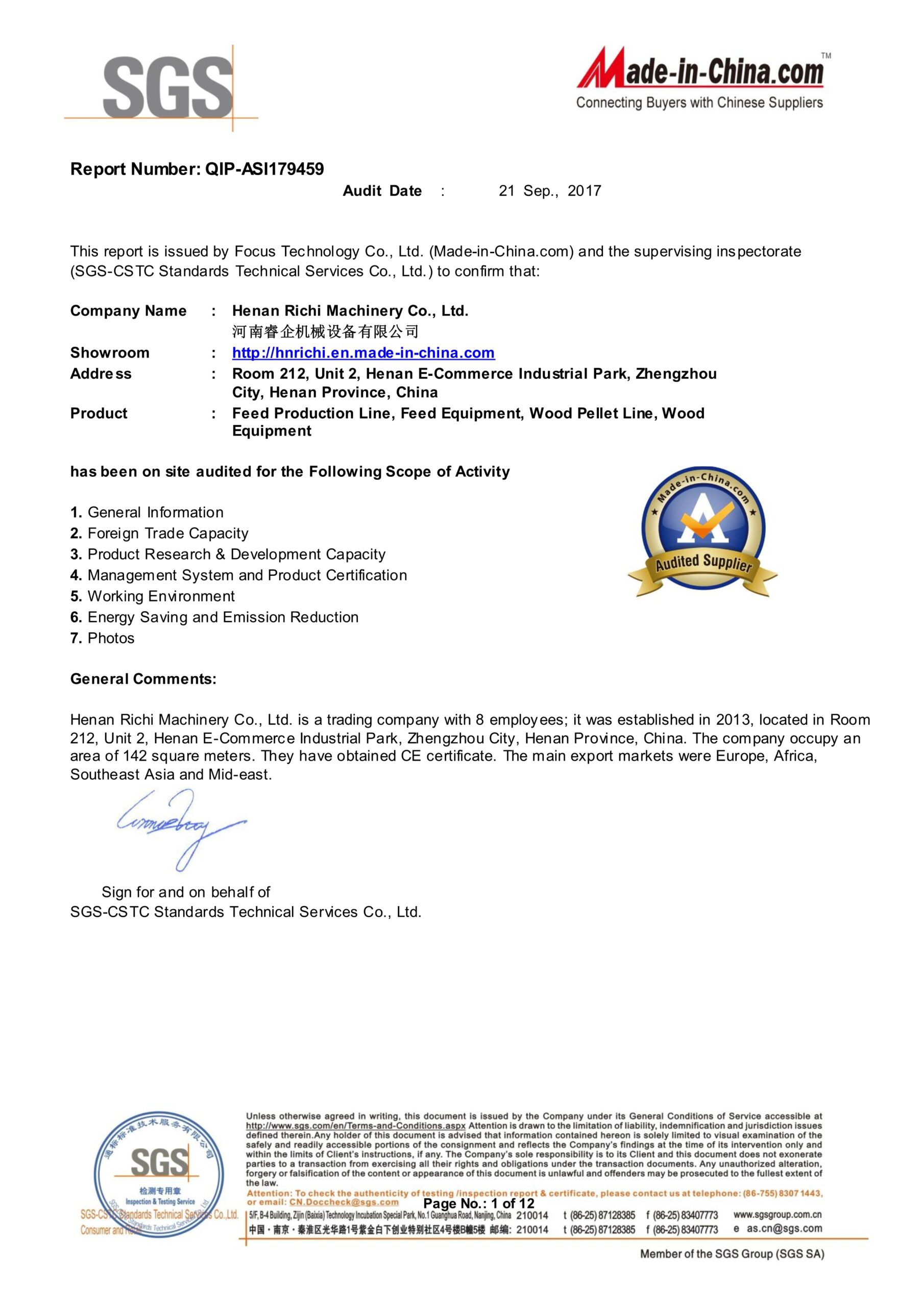

Certificates

01

Accurate Control

We have professional project managers to track the whole process to avoid risks for you and enhance the value of the project.

02

Customize Service

According to the actual needs of customers, a number of process plans are formulated to achieve personalized customization.

03

Site Inspection

View the entire service system from the design team to the maintenance team to witness the realization of the investment value

04

Training support

Our trainers will also continue to follow up the operation of the project to ensure the orderly implementation of the project.

What RICHI Machinery Offer

Customized Solution

According to different needs, in the early stage, we will customize the reasonable equipment configuration of the pellet production line for you to reduce the operating cost in the later stage.

Worldwide Shipping

No matter where you are in the world, our goods will be delivered to you safely.

After Sales

Our professional after-sales team will solve any problems in the pellet production process for you, while providing high-quality product accessories.

Related Equipment About Pellet Production Plant

Wood Pellet Production Line

Biomass Pellet Production Line

Different raw materials can be used in our biomass pellet line, for example wood log, wood sawdust, rice husk, straw, palm shell, EFB, wet or dry grass, alfalfa, hemp, tire fiber, organic fertilizer, waste paper, and so on.