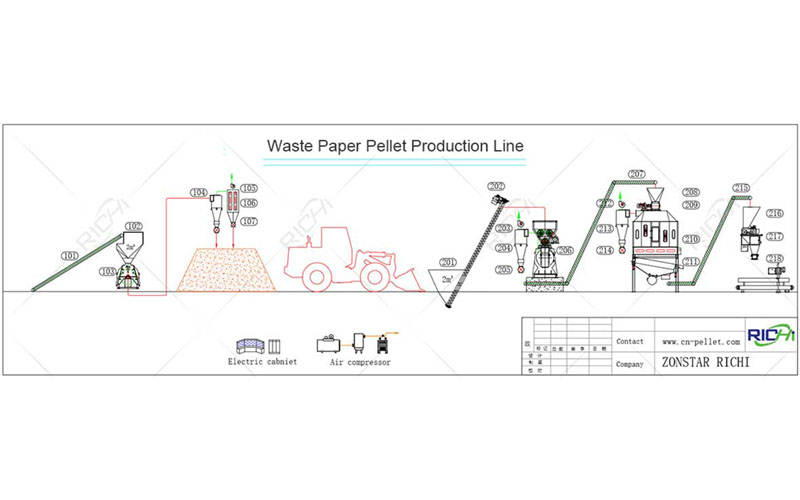

Waste Paper Pellet Production Line

The waste paper pellet production line is a good solution to the problem of urban office and domestic waste discharge. And waste paper pellets have good combustibility and water absorption, very suitable as cat litter pellets or fuel pellets. If you want to build new waste paper pellet mill with RICHI Machinery, just contact us now.

A large part of the municipal solid waste is waste paper, which is a pity to discard. Therefore, more and more businesses invest in the establishment of waste paper pellet production lines to produce waste paper pellets.

Waste Paper Pellet Production Line

RICHI has more than 26 years of experience in manufacturing and exporting pellet production equipment. We provide customers with complete waste paper pellet production line solutions.

Choose RICHI, starting from the scheme design, so that your waste paper pellet production business is no longer difficult.

BRAND

RICHI Machinery

MODEL

Waste Paper Pellet Production Line

CAPACITY

0.5-40TPH<Can Be Customized>

POWER

According to the waste paper pellet production line

Necessary Equipment For Waste Paper Pellet Production Line

- RICHI Waste Paper Crushing Machine for Crushing Materials in Waste Paper Pellet Production Line

- Model: RI-600/RI-800/RI-1000/RI-1200

- Capacity: 0.8-1T/H, 2-4T/H, 4-6T/H, 6-8T/H

- Raw Materials: waste office paper, waste newspapers, waste cardboard, packaging boxes and so on, agricultural and biomass waste can be used as raw materials for pellet production

- RICHI Waste Paper Dryer Machine for Drying Materials in Waste Paper Pellet Production Line

- Model: ф1200*120000, ф1500*150000, ф1800*180000, ф2400*100000, ф2400*100000*3

- Application: Suitable for a large amount of low-temperature continuous drying materials, such as waste office paper, waste newspapers, waste cardboard, packaging boxes and so on.

Waste Paper Pellet Mill

The MZLH series waste paper pellet making machine has a larger ring die and pelletizing chamber to ensure high-efficiency waste paper pellet production.

- Power: 30-300KW

- Capacity: 0.5-10T/H

- Pellet Size: 6-12mm

- Model: SKLN11*11, SKLN14*14, SKLN17*17, SKLN20*20, SKLN24*24

- Capacity: 1.5-2T/H, 3-5T/H, 5-8T/H, 9-12T/H, 13-18T/H

- Application: Cooling of high temperature pellet after pelleting

- Main Application Scenario: waste paper pellet production line post-processing section

- Brand Name: RICHI Waste Paper Pellet Packing Machine

- Model: DCS-C50/D, DCS-A50/D, DCS-B50/D, DCS-B50/S, DCS-A50/Y

- Application: Mainly used in pellet production lines. As the last step of the equipment, the finished product is packaged for storage and transportation.

- Main Application Scenario: finished product packaging section of waste paper pellet production line

Complete Waste Paper Pellet Production Line Flow Chart

Our waste paper pellet production solutions have spread all over the world.

Our waste paper pellet production line can process many kinds of biomass materials

This complete waste paper pellet production line can not only process basic various waste paper and other forestry&agricultural wastes, but also process waste office paper, waste newspapers, waste cardboard, packaging boxes and so on, agricultural and biomass waste.

Until now, we have established a number of pellet production lines and sold them all over the world. Our customers are located in the United States, Canada, the United Kingdom, Russia, France, Greece, Romania, Australia, Argentina, Mexico, Chile, Peru, etc.

If you want to build a waste paper pellet factory, buy waste paper pellet production equipment, please contact us, just tell us your output requirements, and we can customize a suitable waste paper pellet production line for you.