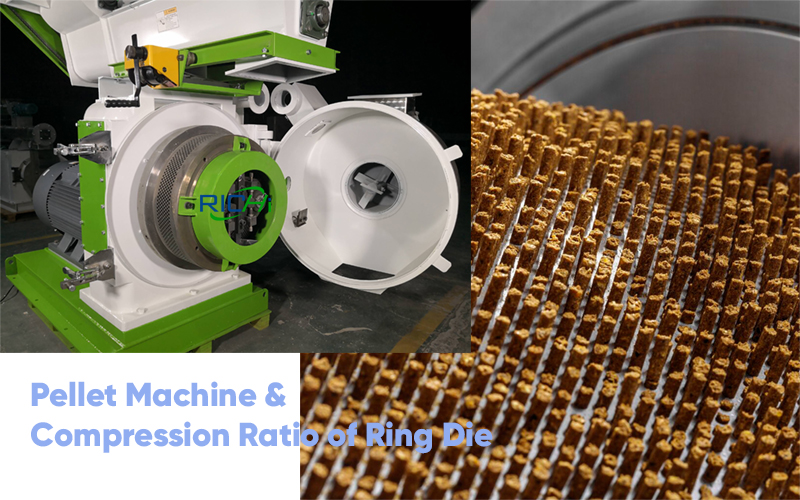

What you should know about the compression ratio of the sawdust pellet machine ring die

Compression ratio of sawdust pellet mill = effective length of die hole / diameter of die hole.

First of all, we advise our customers to pick the right wood chip pellet mill for them, provided that it is equipped with a high quality ring die. According to the specific gravity of the produced material and the type of pellets to be produced, we need to choose the suitable die hole form, opening ratio and compression ratio.

Then, we recommend to choose a ring die with high opening rate. But it is important to make sure that the steel used to produce the ring die is super strong. Because for some materials, if the ring die is not strong enough due to the ring die being too thin while ensuring a reasonable compression ratio, then the die will have bursting appear during the production. Therefore, we suggest to increase the ring die thickness and increase the pressure relief hole under the premise of ensuring the effective length of the die hole. This is to produce pellets more safely.

Ring die compression ratio refers to the ratio of the effective length of the ring die hole and the minimum diameter of the ring die hole, which is a standard indicator reflecting the extrusion strength of wood pellets.

The larger the compression ratio is, the stronger the pellets produced will be. For the compression ratio of ring die with straight hole, the effective length of the ring die hole is the total thickness of the ring die, and the minimum diameter is the diameter of the die hole itself; for the release step hole and the outer cone hole, the effective length of the die hole is the total thickness of the ring die minus the length of the release hole or the length of the outer cone hole.

The small diameter section hole diameter is the compression ratio calculation hole diameter; For compression step holes and inner tapered holes, this case is more special. Generally, the entire ring die thickness is the effective length of the die hole, and the minimum diameter is the small diameter section aperture. Of course, the meaning of the ring die compression ratio calculated in this way is different from the first two cases.

Another important index for measuring the quality of ring die – roughness. At the same compression ratio, the larger the roughness value, the greater the extrusion resistance of the straw particles, the more difficult it is to discharge the material. Excessive roughness can also affect the quality of the pellet surface.

The appropriate roughness value for the ring die compression ratio should be between 0.8 and 1.6.

Therefore it is important for us to understand how to choose the right compression ratio and die for our wood pellet mill.

Pellet Production Line

Core Equipment of Wood Pellet Production Line

RICHI Pellet Machine For Sale

- Wood Pellet Mill For Sale

- Grass Pellet Making Machine For Sale

- Straw Pellet Machine For Sale

- Rice Husk Pellet Machine For Sale

- EFB Pellet Machine For Sale

- Organic Fertilizer Pellet Machine For Sale

- Cat Litter Pellet Making Machine For Sale

- Textile Cord Pellet Machine For Sale

- Paper Pellet Making Machine For Sale

- Pellet Maker For Pellet Stove