What Kind of Machine Turns Wood Chips into Pellets?

In today’s era of pursuing sustainable energy、low carbon and environmentally friendly production, converting wood chips and other biomass waste into pellets is not only an effective way to achieve resource reuse, but also brings innovative solutions to the energy industry. Pellets, as a clean and renewable energy source, are not only used for commercial and domestic heating, but also for industrial power generation, animal beds, etc., and its production process deserves to be explored in depth. In this article, we’ll look at the machinery that transforms wood chips into pellets – the wood pellet mill – how it works, and why specialized equipment is essential to the process.

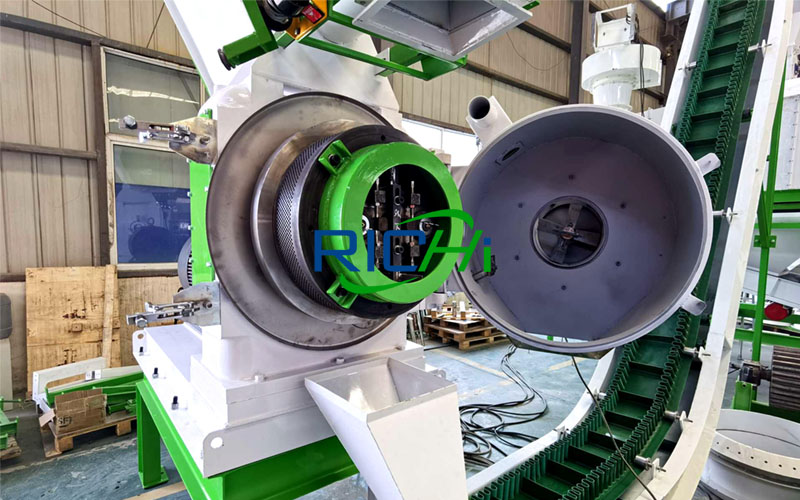

Wood pellet mill

Wood chip pellet mill, also known as biomass pellet mill, is the core equipment for biomass pellet production. It compresses wood chips into solid particles through high pressure, a process that not only improves the burning efficiency of wood chips, but also makes storage and transportation more convenient.

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

|---|---|---|---|---|---|---|

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Pellet Machine Power | 37KW | 55KW | 110KW | 160KW | 250KW | 280KW |

| Capacity(wood sawdust,biomass) | 300-400KG/H | 500-700KG/H | 1.0-1.2 T/H | 2.0-2.5 T/H | 2.5-4 T/H | 3-4.5 T/H |

| Capacity(grass,straw) | 600-800KG/H | 800-1000KG/H | 1.5-2 T/H | 3-4 T/H | 5-7 T/H | 8-10 T/H |

| Capacity(organic fertilizer) | 1-2 T/H | 3-4 T/H | 5-6 T/H | 7-8 T/H | 9-10 T/H | 10-12 T/H |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

| Weight(KG) | 2500 | 3500 | 4000 | 4500 | 5000 | 5500 |

| Dimension(mm) | 2200*900*1300 | 2500*1100*1600 | 2800*1150*1730 | 3000*1260*1860 | 3300*1500*2000 | 3500*1600*2180 |

Auxiliary equipment

- Crusher: It is used to crush larger wood pieces into small pieces suitable for pelletizing.

- Dryer: to adjust the humidity of wood chips to ensure the quality of pellets.

- Cooling system: cool the newly made hot pellets to prevent sticking due to high temperature.

- Sieving machine: removing unshaped pellets and dust to ensure the quality of finished products.

Let’s elaborate on the various aspects of the wood pellet mill production process to clearly demonstrate the transformation from raw material to finished pellets.

1. Raw material preparation

First, the raw materials (usually wood chips, branches, sawdust, etc.) are collected and transported to the production plant. The type of feedstock directly affects the quality and combustion efficiency of the pellets. Therefore, the selection and preparation of the feedstock is crucial at this stage.

2. Crushing

Large pieces of wood and branches are not suitable for direct pelletizing and must therefore be crushed through a crusher. The crusher breaks these larger pieces into smaller pieces so that they are the right size for the next step of the pelletizing process. This step ensures the homogenization of the raw material and lays the foundation for the production of high quality wood pellets.

3. Drying

Crushed wood chips contain a certain amount of moisture, if the moisture is too high or too low, it will affect the quality of the pellets. Therefore, the wood chips must be dried through a dryer to adjust the moisture content to a suitable level (usually between 10% and 15%). Appropriate moisture content helps to improve the molding rate and quality of pellets.

4. Pelletizing

The dried wood chips are fed into a wood pellet mill. Under high pressure and friction, the wood chips are compressed into pellet shape. During this process, the lignin of the wood chips acts as a natural binder to help the pellets retain their shape. Pelletizing is the most critical part of the entire production process.

5. Cooling and curing

Freshly made woodchip pellets are hot and need to be cooled through a cooling machine. Cooling not only reduces the temperature of the pellet, but also helps the pellet to further cure and stabilize its shape. The cooled pellets have better hardness and durability.

6. Sieving

After cooling, the pellets may be accompanied by some fine fragments and dust. These impurities can be removed by sieving in a sieving machine to ensure the purity and quality of the finished granules.

7. Packaging

The sieved high quality wood pellets are finally packaged and ready for sale or use. Packaging not only facilitates transportation and storage, but also protects the pellets from the external environment.

The entire wood pellet production process is a complex but efficient process involving multiple steps from raw material handling to final product packaging. Each step requires precise handling and specialized equipment to ensure the production of high quality wood pellets. This demonstrates why specialized production equipment and technical support are indispensable; simple DIY equipment can hardly meet the standards and efficiency of industrial production.

While DIY (Do It Yourself) pellet production equipment may seem like an affordable option initially, especially for small-scale production or personal use, it is often wiser in the long run to go with specialized pellet production equipment. Here are some key reasons why choosing DIY pellet production equipment is not recommended:

- Inefficiency

The production efficiency of DIY pellet machines is usually much lower than that of professional equipment. Professional pellet production lines are carefully designed to run continuously and have a high processing capacity to produce large quantities of pellets in a relatively short period of time. In contrast, DIY equipment may have slow processing speeds and low production volumes due to design and performance limitations, making it difficult to meet higher production demands.

- Quality control difficulties

Manufacturing high-quality wood pellets requires precise control of the type, size and moisture content of the raw material, as well as factors such as pressure and temperature during the production process. Professional pellet mill equipment is usually equipped with a precise control system to regulate these parameters and ensure the quality of the pellets. DIY equipment often lacks this fine control capability, resulting in inconsistent quality of the pellets produced, which may affect the use of the final product.

- Safety hazards

The pellet production process involves high-pressure compression and high-temperature operation, which requires high safety performance of the equipment. Professional equipment is usually designed with these safety factors in mind, while DIY equipment may not have adequate safety protection measures and pose potential safety risks.

- Maintenance and after-sales service

Professional pellet mill equipment usually comes from reputable manufacturers that offer comprehensive maintenance and after-sales services. If there is any problem with the equipment, you can get professional technical support and repair service quickly. In contrast, DIY equipment often lacks such support, and once a malfunction occurs, repairing and solving the problem may become difficult and expensive.

- Economic benefits for long-term consideration

Although the initial investment in DIY equipment may be low, considering its low productivity, potential safety risks, quality control issues, and the difficulty and cost of maintenance, investing in professional pellet production equipment tends to be more economically beneficial in the long run.

While DIY pellet production equipment may seem like an attractive option in some cases, its limitations and potential problems make it difficult to meet the demands of efficient, safe and consistent production. Choosing a professional pellet mill manufacturer that not only ensures production efficiency and pellet quality, but also provides the necessary safety, security and technical support is a smart choice for achieving long-term production goals and securing a return on investment.

RICHI Machinery, as a leading supplier of wood pellet mill and the entire biomass pellet production line equipment, provides comprehensive one-stop solutions to customers with its rich industry experience and expertise. Below is a detailed description of how RICHI Machinery helps customers with the whole process support from equipment selection to production line operation:

Equipment Selection

- Personalized Consultation: RICHI Machinery’s team of experts will first understand the customer’s specific needs, including production capacity, type of raw material, budgetary constraints, etc., and based on this information will provide personalized recommendations for equipment selection.

- Product Versatility: The company offers a wide range of equipment options, from small domestic pellet mills to large industrial pellet lines, catering to customers of different sizes and needs.

Wood Pellet Line Design

- Customized Design: RICHI Machinery offers customized line design services based on the customer’s plant layout, budget and production goals to ensure that each line maximizes efficiency and output.

- Advanced Technology: Utilizing the latest technology and innovative designs, RICHI Machinery’s line designs emphasize energy efficiency and ease of operation to reduce production costs and improve product quality.

Installation and Commissioning

- Professional Installation Team: RICHI Machinery has an experienced installation team that is responsible for on-site installation and commissioning of the equipment to ensure the smooth operation of each unit and the entire line.

- Training Support: In addition to equipment installation, RICHI also provides customers with operation and maintenance training to ensure that the customer’s employees are proficient in the daily operation and basic maintenance of the production line.

After Sales Service

- Round-the-clock service: RICHI Machinery provides 24-hour after-sales service to answer any questions customers may have and to ensure the stable operation of the production line.

- Spare parts supply: Rapid response spare parts supply system ensures that customers can get the required spare parts in time to minimize downtime.

Professional Advantages

- Rich experience: With years of experience in the pellet mill industry, RICHI Machinery has helped hundreds of customers around the world to set up and operate pellet production lines by continuously optimizing its products and services.

- Technological Innovation: The company emphasizes on technological development and innovation, and continues to introduce more efficient and environmentally friendly solutions for biomass pellet production.

- Customer Satisfaction: Customer satisfaction has always been the core of RICHI Machinery’s work, the company is committed to providing high-quality products and services, and has won the widespread recognition and trust of customers.

RICHI Machinery by providing one-stop pelletizing solution from equipment selection, production line design, installation and commissioning to after-sales service. With our experience and professional advantages in the pellet mill industry, we are a reliable partner to support our customers with efficient, stable and economical pellet production lines.

RICHI Machinery provides immense value to its customers across the globe with its significant strengths in productivity, technological innovations, quality control, customer service and logistic arrangements.

Production Capability

- High Efficiency Equipment: RICHI Machinery’s pellet mills and production lines are designed with high efficiency to ensure high quality pellet production and high output to meet the needs of our customers for large scale production.

- High degree of automation: The automated control system reduces the need for labor and lowers production costs, while improving the stability and reliability of the production process.

Technological Innovation

- Continuous R&D: RICHI Machinery invests a lot of resources in research and development of new technologies and products to ensure that the company maintains a leading position in the field of biomass energy and feed pellet mills.

- Customized Solutions: Based on the specific needs of our customers, RICHI Machinery is able to provide customized machinery and production lines to best meet their production requirements.

Quality Control

- Strict standards: RICHI Machinery strictly implements the international quality management system standards during the production process to ensure the quality of each machine and each production line.

- Quality Inspection: All the equipments are strictly tested and inspected before leaving the factory to ensure that the equipments are delivered to the customers with excellent performance, stability and reliability.

Customer Service

- Full range of services: From pre-consultation, project design, equipment installation and commissioning to after-sales service, RICHI Machinery provides a full range of one-stop services to ensure that every customer’s needs can be met.

- Technical support: RICHI Machinery has a professional technical support team, which can quickly respond to customer needs and provide professional guidance and assistance.

Logistics Arrangement

- Efficient logistics: RICHI Machinery has established a good relationship with many logistics companies, which can provide customers with fast and safe logistics services to ensure that the equipment is delivered on time.

Global Transportation: No matter where the customer is located in the world, RICHI Machinery can ensure the safe and on-time arrival of the equipment through its strong logistics network.

RICHI Machinery provides value to its customers beyond expectations through its strengths in productivity, technological innovation, quality control, customer service and logistic arrangements. These strengths have not only made RICHI Machinery a leader in the pellet mill industry, but have also made it a trusted partner for its customers worldwide.

In today’s context of pursuing sustainable resource utilization and environmentally friendly production, the conversion of biomass waste such as wood chips into energy pellets not only optimizes resource recycling, but also brings green innovation to the energy industry. However, the establishment and operation of a pellet production line is not a simple task. It involves a series of complex engineering techniques and process management, from the pre-treatment of raw materials to the packing and transportation of the final product, each step of the process requires precise control and management to ensure the efficient production and quality assurance of the final pellets.

The complexity of pellet production is reflected in the need for precise control of the nature of the raw material, the adjustment of technical parameters during the production process, the efficient and synergistic operation of the equipment, and the strict monitoring of the quality of the final product. These requirements are not only supported by high-performance equipment, but also by specialized knowledge and experienced technical teams.

In this process, the selection of a specialized pellet mill equipment supplier like RICHI Machinery is crucial to ensure the success of the entire project. RICHI Machinery not only provides advanced and reliable equipment, but also offers comprehensive support from biomass pellet production line design to installation and commissioning, and from technical training to after-sales service, to help the customer to overcome the challenges of the process and achieve both productivity and product quality. RICHI Machinery not only provides advanced and reliable equipment, but also provides comprehensive support from design to installation and commissioning, from technical training to after-sales service, to help customers overcome all the challenges in the production process, and realize the double guarantee of production efficiency and product quality.

Choosing RICHI Machinery means choosing a strong partner, which ensures that customers get the maximum return on their investment by providing efficient production solutions and professional services. Whether it is wood chips, sawdust or any other biomass material, RICHI Machinery’s pellet production lines are able to transform it into high-value energy pellets, helping customers to achieve their sustainable development goals.

Looking back at the overview of pellet production lines at the beginning of this article, we can see that the process of turns wood chips into pellets is not only environmentally and economically valuable, but also a technical and managerial challenge. Therefore, choosing a professional equipment and technical support provider when investing in a pellet production project is the key to ensuring the success of your project, and RICHI Machinery, with its technical expertise, quality equipment and comprehensive services, will be your strong backing on the path of biomass pellet production.

Pellet Production Line

Core Equipment of Wood Pellet Production Line

RICHI Pellet Machine For Sale

- Wood Pellet Mill For Sale

- Grass Pellet Making Machine For Sale

- Straw Pellet Machine For Sale

- Rice Husk Pellet Machine For Sale

- EFB Pellet Machine For Sale

- Organic Fertilizer Pellet Machine For Sale

- Cat Litter Pellet Making Machine For Sale

- Textile Cord Pellet Machine For Sale

- Paper Pellet Making Machine For Sale

- Pellet Maker For Pellet Stove