Why do we recommend choosing a ring die pellet machine?

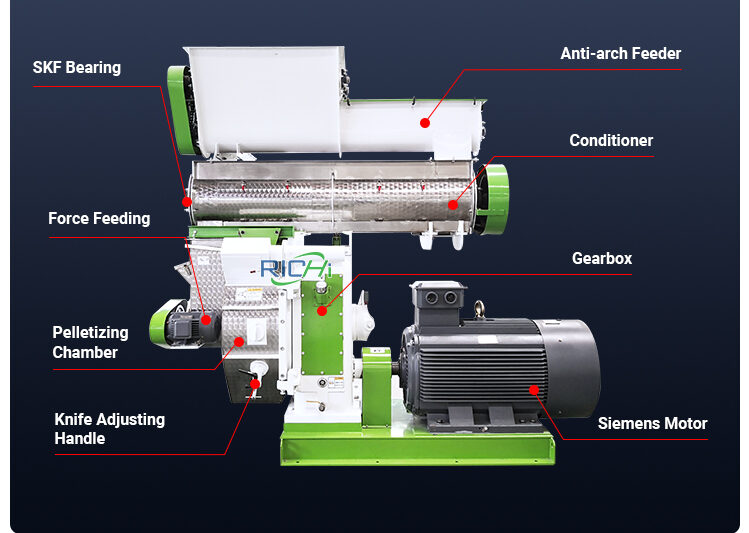

Ring die pellet machine is one type of pelletizing equipment. It is commonly used in the production of animal feed, wood pellets, and biofuels. This kind of pellet machine is known for its efficiency, durability, and ability to produce high-quality pellets on a large scale.

The feeder feeds raw materials such as sawdust, shavings, and other biomass into the pelletizer chamber, forming pellets through high temperature and pressure. The ring die has small holes, called die holes, that are spaced evenly around its circumference. As the raw materials are forced through the die-holes, they are compressed and shaped into small, uniformly-sized pellets.

One of the key advantages of the ring die pellet machine is its ability to produce high-quality pellets. Because the raw materials are forced through the die holes under high pressure, the resulting pellets are dense and have a smooth, uniform surface. This makes them less susceptible to breakage and easier to handle, which is important for applications such as animal feed where the pellets need to be transported and stored.

Another advantage of the ring die pellet machine is its efficiency. Because the raw materials are forced through the die holes under high pressure. The pellet machine can produce a large number of pellets in a short amount of time. This makes it an ideal choice for large-scale pellet production, where speed and efficiency are crucial.

Ring Die Pellet Mill For Sale

MZLH320 series ring die wood pellet machine ensures high capacity and efficient control of the pelleting process. The wood pellet mill machine is dimensioned for large and designed with exchangeable wear parts.

- Power: 37KW

- Capacity: 600-800KG/H

- Pellet Size: 6-12mm

MZLH350 series ring die wood pellet making machine has wide adaptability. According to different raw materials, different pellets can be produced. Larger feeders increase production capacity and ensure production efficiency.

- Power: 55KW

- Capacity: 800-1000KG/H

- Pellet Size: 6-12mm

This ring die electric wood pellet mill is recommended for straw pellet production plant. Due to the power and voltage, it is not recommended for household pelletizing. It is very suitable for making straw pellets, alfalfa pellets, forage pellets, wood sawdust pellets, and other biomass pellets.

- Power: 110KW

- Capacity: Capacity: 1.5-2T/H

- Pellet Size: 6-12mm

The MZLH520 series wood pellet maker has a larger ring die and pelletizing chamber to ensure high-efficiency straw pellet production. In order to adapt to lighter raw materials, we have added a forced feeder.

- Power: 160KW

- Capacity: 3-4T/H

- Pellet Size: 6-12mm

MZLH768 series large commercial wood pellet press is mainly used for the production of biomass pellets. Enlarged feeders and larger ring die sizes are more suitable for straw pellet plants.

- Power: 250KW

- Capacity: 5-7T/H

- Pellet Size: 6-12mm

RICHI wood pelletizer for sale. 27 years of pelleting plant experience, professional design and manufacturing team, overseas installation engineers, competitive factory direct sales prices. Advanced pelleting process technology.

- Power: 280KW

- Capacity: 8-10T/H

- Pellet Size: 6-12mm

Ring Die Pellet Machine Technical Parameter

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

|---|---|---|---|---|---|---|

| Anti-caking Feeder Power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 3KW | 3KW |

| Forced Feeder Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 1KW | 1KW |

| Pellet Machine Power | 37KW | 55KW | 110KW | 160KW | 250KW | 280KW |

| Capacity(wood sawdust,biomass) | 300-400KG/H | 500-700KG/H | 1.0-1.2 T/H | 2.0-2.5 T/H | 2.5-4 T/H | 3-4.5 T/H |

| Capacity(grass,straw) | 600-800KG/H | 800-1000KG/H | 1.5-2 T/H | 3-4 T/H | 5-7 T/H | 8-10 T/H |

| Capacity(organic fertilizer) | 1-2 T/H | 3-4 T/H | 5-6 T/H | 7-8 T/H | 9-10 T/H | 10-12 T/H |

| Final Pellet | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm | 6-12mm |

| Weight(KG) | 2500 | 3500 | 4000 | 4500 | 5000 | 5500 |

| Dimension(mm) | 2200*900*1300 | 2500*1100*1600 | 2800*1150*1730 | 3000*1260*1860 | 3300*1500*2000 | 3500*1600*2180 |

In addition to their efficiency and ability to produce high-quality pellets, ring die pellet machines are known for their standardization and durability. RICHI pellet machine is made of high-strength steel over 6mm. This allows it to withstand the high pressures and temperatures involved in pellet production. This also means that the machine can run continuously for a long time, reducing downtime for maintenance or repair.

One of the key factors that affect the ring die pellet machine performance is the size and shape of the die holes. The size of the die holes determines pellets size. And the shape of the holes affects the density and surface smoothness of the pellets. So, it is important to carefully select the die-holes for a given application to ensure that the resulting pellets meet the desired specifications.

In conclusion, the ring die pellet machine is a versatile and efficient piece of equipment that is widely used in the production of animal feed, wood pellets, and biofuels. Its ability to produce high-quality pellets on a large scale, combined with its durability and efficiency, make it an important tool for many industrial and commercial applications.

Pellet Production Line

Core Equipment of Wood Pellet Production Line

RICHI Pellet Machine For Sale

- Wood Pellet Mill For Sale

- Grass Pellet Making Machine For Sale

- Straw Pellet Machine For Sale

- Rice Husk Pellet Machine For Sale

- EFB Pellet Machine For Sale

- Organic Fertilizer Pellet Machine For Sale

- Cat Litter Pellet Making Machine For Sale

- Textile Cord Pellet Machine For Sale

- Paper Pellet Making Machine For Sale

- Pellet Maker For Pellet Stove