2021 Biomass Pellet Mill Functional Advantages Encyclopedia

Biomass pellet mill is a device that pulverizes paulownia, poplar, cypress, fruit trees, various crop straws, bamboo chips, etc. into powder and processes them into biomass fuel pellets. According to different raw materials, biomass pellet machines can also be called wood pellets machine, creatinine pellets machine, sawdust pellets machine, bamboo pellets machine, fuel pellets machine, straw pellets machine, rice husk pellets machine, etc.; also called biomass pellet mill, biomass pelletizer. Although the name of the pellet machine is different, they are all the same kind of machine.

Ⅰ- Introduction of biomass pellet mill

- RICHI Biomass Pellet Mill can produce biomass pellets with various raw materials such as wood chips, straw, chaff and so on.

- Adopting various molding technologies such as cold pressing and extrusion molding. The grease polishing and shaping process makes the biomass particles beautiful in appearance and compact in structure.

- RICHI Biomass Pellet Machine has high output, low energy consumption, low noise, low failure, strong fatigue resistance, continuous production, economical and durable;

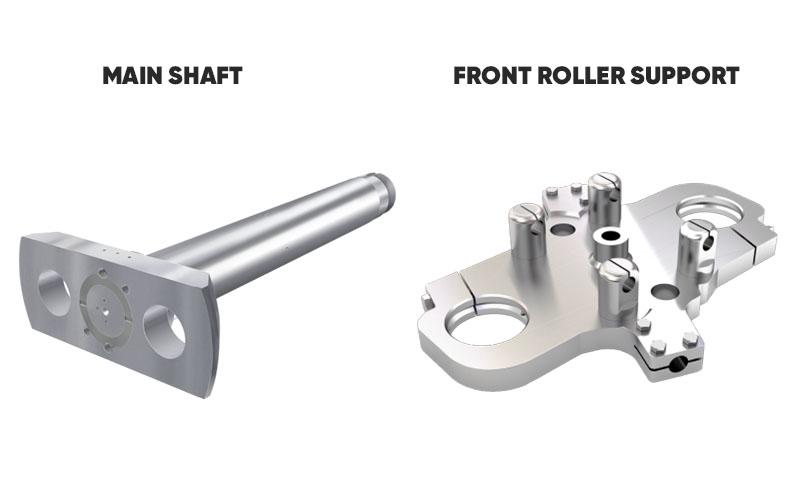

- The whole machine adopts special high-quality materials and advanced connecting shaft transmission device. The key components adopt high-quality alloy steel and wear-resistant materials. The service life is extended by 5-7 times by using German vacuum furnace for heat treatment.

Ⅱ - Purpose of biomass pellet mill

Biomass pellet mill is a pellet fuel making machine that uses various branches, wood, wood sawdust, corn stalk scales, rice straw, straw scales, sawdust, wood flour, sawdust and other agricultural wastes as raw materials. The pellets can be used in fireplaces, boilers, and biomass power plants.

Ⅲ - Classification of biomass pellet mill

According to the different ring die used, it can be divided into flat die pellet machine and ring die pellet machine, and ring die pellet machine can be divided into vertical ring die pellet machine and horizontal ring die pellet machine.

Ⅳ - Features of biomass pellet mill

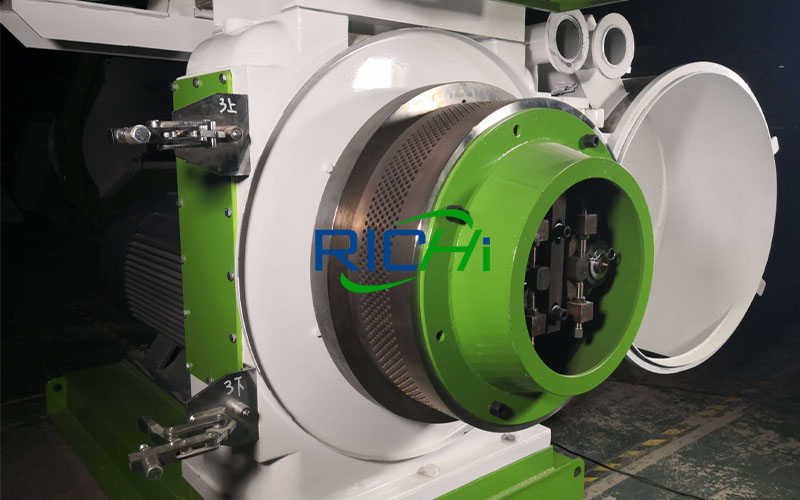

The main drive of RICHI ring die biomass pellet mill adopts high-precision gear transmission, the ring die adopts quick-release hoop type, and the transmission part of the whole machine adopts high-quality bearings to ensure high-efficiency, stable transmission and low noise. The ring die adopts quick-release hoop. The hoop type, the feeding adopts frequency control feeding to ensure uniform feeding, the door cover is equipped with a strong feeder, a compensating snake-shaped spring coupling with an international advanced level, and has a novel structure, compactness, safety, and low noise. Low failure performance.

RICHI ring die biomass pellet mill adopts international advanced manufacturing technology and can tailor high-quality molds for various raw materials for your various pellet machines, which will extend the life of your equipment, improve product quality, and reduce consumption costs per ton.

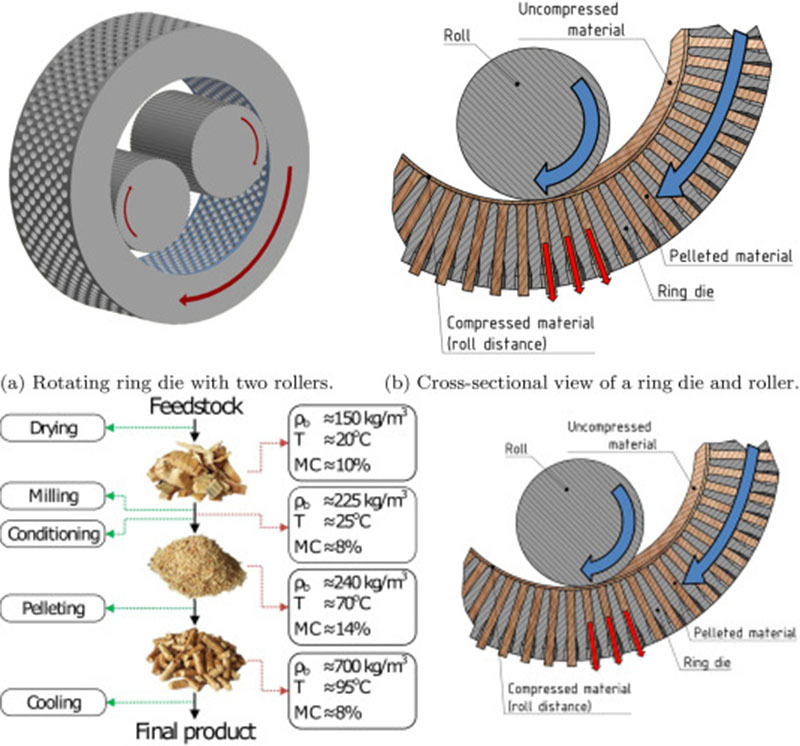

Ⅴ - Working principle of biomass pellet mill

Adopt the principle of interaction between the pressing force and friction force between the press roller and the ring die, so that the material can be shaped. There is no need to add any additives or binders during the processing of the materials. Materials such as straw scales contain a certain amount of cellulose and lignin. The lignin is a structural monomer in the material and is a high molecular compound of phenylpropane type. It has the function of strengthening cell wall and binding cellulose. Lignin is non-crystalline, the main part is insoluble in any solvent at room temperature, has no melting point, but has a softening point. When the temperature reaches a certain value, the softening and cohesive force of lignin will increase, and under a certain pressure, the cellulose molecular cluster will be dislocated, deformed, and stretched.

Ⅵ - Advantages of RICHI biomass pellet mill

- High-precision involute cylindrical helical gear is used for direct transmission, and the transmission efficiency is as high as 98%.

- After the transmission gear blank is water-forged, the normalizing heat treatment improves the hardness of the tooth surface; the tooth surface is carburized, and the carburized layer is 2.4mm deep to enhance the wear resistance and extend the service life of the parts; hard teeth The surface is processed by silent fine grinding and edge trimming process, which makes the operation quieter and more stable.

- Safe operation provides more reliable guarantee.

- The main biomass pellet mill cabinet is made of high-quality steel, with uniform thickness and compact structure; it is carefully processed by the Swiss imported CNC machining center, and the machining accuracy is zero error. Provide stronger support for normal operation.

- The bearings and oil seals used in the transmission part adopt high-precision bearings imported from Japan and wear-resistant and temperature-resistant fluorine rubber oil seals imported from the United States, and a lubrication oil return system is specially added, and the oil circuit is circulated and cooled, and the oil is automatically lubricated at regular intervals. Ensure that the bearings are fully lubricated, and the operation is safer and more reliable.

- The bearings used in the pellet forming system are all high-quality silent bearings, and the thin oil circulating cooling and lubricating system is added, so the bearing life is longer and the operation is safer.

- The ring die is made of high-grade stainless steel and high-nickel steel. The unique compression ratio design is reasonable, so that the product quality is better, the ring die has a longer service life, and the production cost is minimized.

- The new generation of biomass pellet mill is developed and designed by RICHI senior designers, specifically for various biomass pellets. The company has its own production base. The ring die biomass pellet machine is the most stable, most reliable, most efficient, safest and most economical model after hundreds of tests and demonstrations in the factory.

Ⅶ - Raw materials

- The raw material sources of biomass pellets are very wide;

- Sawdust, shavings, bark, sanding powder, waste wood, branch wood produced in wood processing and wood-based panel production;

- Other types of combustible biomass are used as raw materials, without the need to add any adhesives, through equipment processing, can be used to produce biomass pellet fuel.

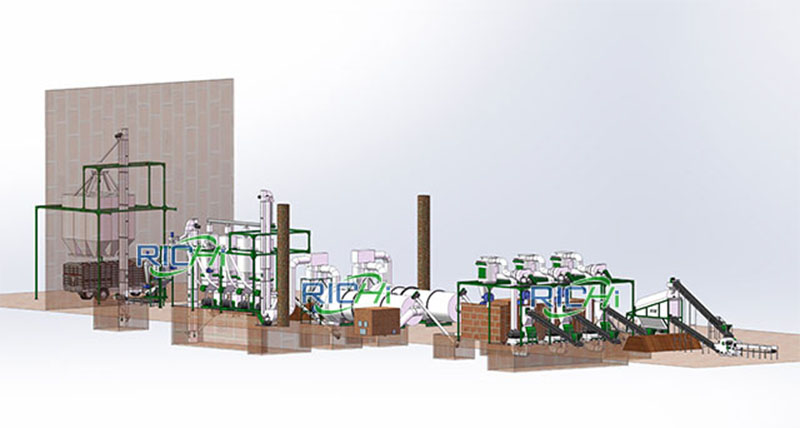

Ⅷ - Biomass pellet mill production process

Raw material collection → raw material crushing → raw material drying → mechanical granulation and forming → mechanical cooling → bagging and sales. (See the picture below:)

Ⅸ - Finished fuel pellets by biomass pellet mill

1. Introduction to biomass fuel pellets

Biomass fuel is the use of corn stalks, wheat straw, rice straw, peanut husks, corn cobs, cotton solid wastes such as flower stalks, soybean stalks, weeds, branches, leaves, sawdust, bark, etc. are used as raw materials, which are crushed, pressurized, densified, and shaped to become small rod-shaped solid particle fuels. Pellets are made by squeezing raw materials such as wood chips and straw scales using a pressing wheel and a ring die at room temperature.

2. Product characteristics of biomass pellet fuel

Reasonably control the humidity of the raw materials, so that the product has high calorific value, low moisture content, sufficient combustion, low ash content, and will not agglomerate after combustion, avoid blocking the combustion machine gun, and reduce the damage to the combustion equipment. The high calorific value reaches about 4480M/KG, the low calorific value reaches about 4038MI/KG, and the quality is qualified.

In order to facilitate the transportation and the different needs of customers, it is divided into 25KG/bag, 100OKG/bag and bulk. The product meets the current demand for low carbon emissions, and its technical performance indicators in all aspects meet the national standards; transportation and storage are extremely convenient, and the combustion efficiency is high.

It can replace coal, oil and other fuels to reduce pollution. It is used as a boiler fuel. It can replace non-renewable fuels such as coal and heavy oil to reduce pollution. It is used as boiler fuel. It is an environmentally friendly product that can replace non-renewable resources such as coal and heavy oil. It is widely used in boiler combustion and other fields.

3. Advantages of biomass fuel pellets:

- Small size, convenient for storage and transportation, reducing transportation cost.

- High combustion efficiency, easy to burn out, and little residual carbon.

- When biomass pellets burn, the content of harmful gas components is extremely low, and the harmful gas emitted is less, which has environmental protection benefits.

Learn more about biomass pellet mill:

Pellet Production Line

Core Equipment of Wood Pellet Production Line

RICHI Pellet Machine For Sale

- Wood Pellet Mill For Sale

- Grass Pellet Making Machine For Sale

- Straw Pellet Machine For Sale

- Rice Husk Pellet Machine For Sale

- EFB Pellet Machine For Sale

- Organic Fertilizer Pellet Machine For Sale

- Cat Litter Pellet Making Machine For Sale

- Textile Cord Pellet Machine For Sale

- Paper Pellet Making Machine For Sale

- Pellet Maker For Pellet Stove